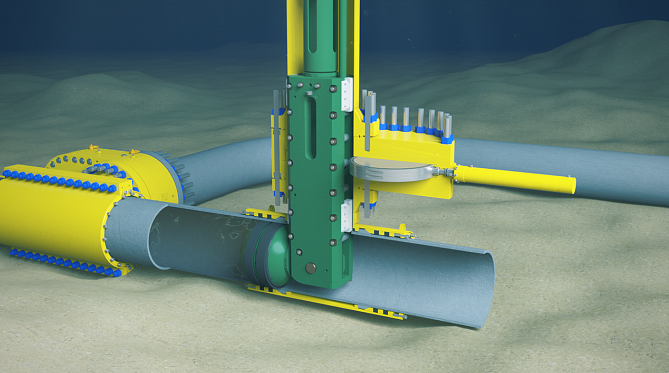

A line plugging machine is an essential tool in industrial operations, enabling maintenance, repairs, and modifications of pipelines without interrupting the flow of materials. Industries that rely on continuous production processes, such as oil and gas, water management, and manufacturing, depend on high-quality equipment to avoid costly downtime. Choosing a reliable line plugging machine manufacturer ensures that businesses benefit from durable, efficient, and safe solutions for their pipeline operations.

Understanding Line Plugging Machines

A line plugging machine manufacturer designs and produces equipment that temporarily seals off sections of pipelines, allowing maintenance or modifications without shutting down the entire system. This process is crucial for industries that need to maintain operational efficiency while ensuring worker safety. High-quality line plugging machines provide a controlled and secure method for isolating pipeline sections, preventing leaks, and reducing environmental risks. Businesses that invest in machines from a trusted line plugging machine manufacturer benefit from enhanced operational reliability and compliance with industry regulations.

Key Applications of Line Plugging Machines

Oil and Gas Industry

The oil and gas sector relies heavily on line plugging machine manufacturers to provide robust solutions for maintaining pipeline integrity. In this industry, pipelines transport crude oil, natural gas, and refined products across vast distances. Any disruption can lead to significant financial losses and safety hazards. By using high-quality equipment from a reputable line plugging machine manufacturer, operators can conduct repairs and upgrades without shutting down entire systems. This technology ensures that production continues while maintenance teams safely address pipeline concerns.

Water and Wastewater Management

Municipal water systems and wastewater treatment facilities must remain operational at all times to serve communities effectively. A trusted line plugging machine manufacturer provides solutions that allow repairs and upgrades without disrupting water supply. When leaks or damages occur in underground pipelines, using line plugging machines helps isolate affected areas while keeping the rest of the system running. This application is particularly important in urban environments where service interruptions can have widespread consequences.

Chemical Processing Plants

Chemical processing plants handle hazardous materials that require careful handling during maintenance operations. A well-established line plugging machine manufacturer ensures that businesses in this industry can safely isolate sections of their pipelines without exposing workers to dangerous substances. Using high-quality plugging machines minimizes the risk of leaks, protects the environment, and ensures compliance with strict safety regulations. Additionally, these machines help chemical plants optimize their maintenance schedules by reducing unplanned downtime.

Power Generation and Utilities

Power plants, including thermal, nuclear, and renewable energy facilities, depend on complex pipeline networks to transport steam, fuel, and cooling water. A leading line plugging machine manufacturer provides solutions that enable power plants to maintain and upgrade their pipelines without affecting electricity generation. By using line plugging machines, maintenance teams can work on specific sections of a pipeline while keeping the rest of the system operational. This approach significantly enhances efficiency and reduces the risk of power outages.

Manufacturing and Industrial Facilities

Factories and industrial facilities utilize pipelines to transport fluids, gases, and chemicals essential for production processes. Any disruption in these systems can lead to delays and financial losses. A trusted line plugging machine manufacturer offers equipment that allows businesses to conduct pipeline maintenance with minimal impact on daily operations. By integrating advanced plugging technology, manufacturers can improve workplace safety, reduce maintenance costs, and enhance overall productivity.

Choosing a Trusted Manufacturer for Line Plugging Machines

Selecting the right line plugging machine manufacturer is crucial for ensuring the reliability and safety of pipeline maintenance operations. Here are some key factors to consider:

- Quality and Durability: A reputable manufacturer designs machines with high-quality materials to withstand extreme conditions and long-term use.

- Industry Experience: Partnering with an experienced line plugging machine manufacturer ensures access to expert guidance and proven solutions.

- Compliance with Safety Standards: Top manufacturers ensure that their equipment meets regulatory requirements for safety and environmental protection.

- Customer Support and Technical Assistance: A reliable line plugging machine manufacturer provides ongoing support, training, and troubleshooting assistance to maximize the effectiveness of their products.

By prioritizing these factors, businesses can choose a manufacturer that delivers efficient and safe solutions for their pipeline maintenance needs.

Future Trends and Innovations in Line Plugging Technology

The pipeline maintenance industry is evolving rapidly, with new technologies improving the performance and efficiency of line plugging machines. Leading line plugging machine manufacturers are integrating automation, digital monitoring, and smart sensors into their equipment. These advancements enable real-time tracking of pipeline conditions, predictive maintenance, and enhanced safety features. Additionally, sustainable innovations, such as eco-friendly sealing materials and energy-efficient designs, are gaining popularity. As technology continues to advance, businesses can expect even more reliable and cost-effective solutions from trusted line plugging machine manufacturers.

Takeaway

The applications of line plugging machines span multiple industries, from oil and gas to water management, chemical processing, and power generation. These machines play a critical role in ensuring that pipelines remain operational while undergoing maintenance. Choosing a reputable line plugging machine manufacturer is essential for securing high-quality equipment that enhances efficiency, safety, and compliance with industry standards. Businesses looking to optimize their pipeline maintenance strategies should partner with a manufacturer that offers reliable solutions, technical expertise, and continuous support.

For those in need of high-performance line plugging machines, selecting a trusted line plugging machine manufacturer is the key to achieving long-term operational success.